Research

Resilient Vehicular Networked Systems: Stochastic Safety, Efficiency and Cybersecurity

|

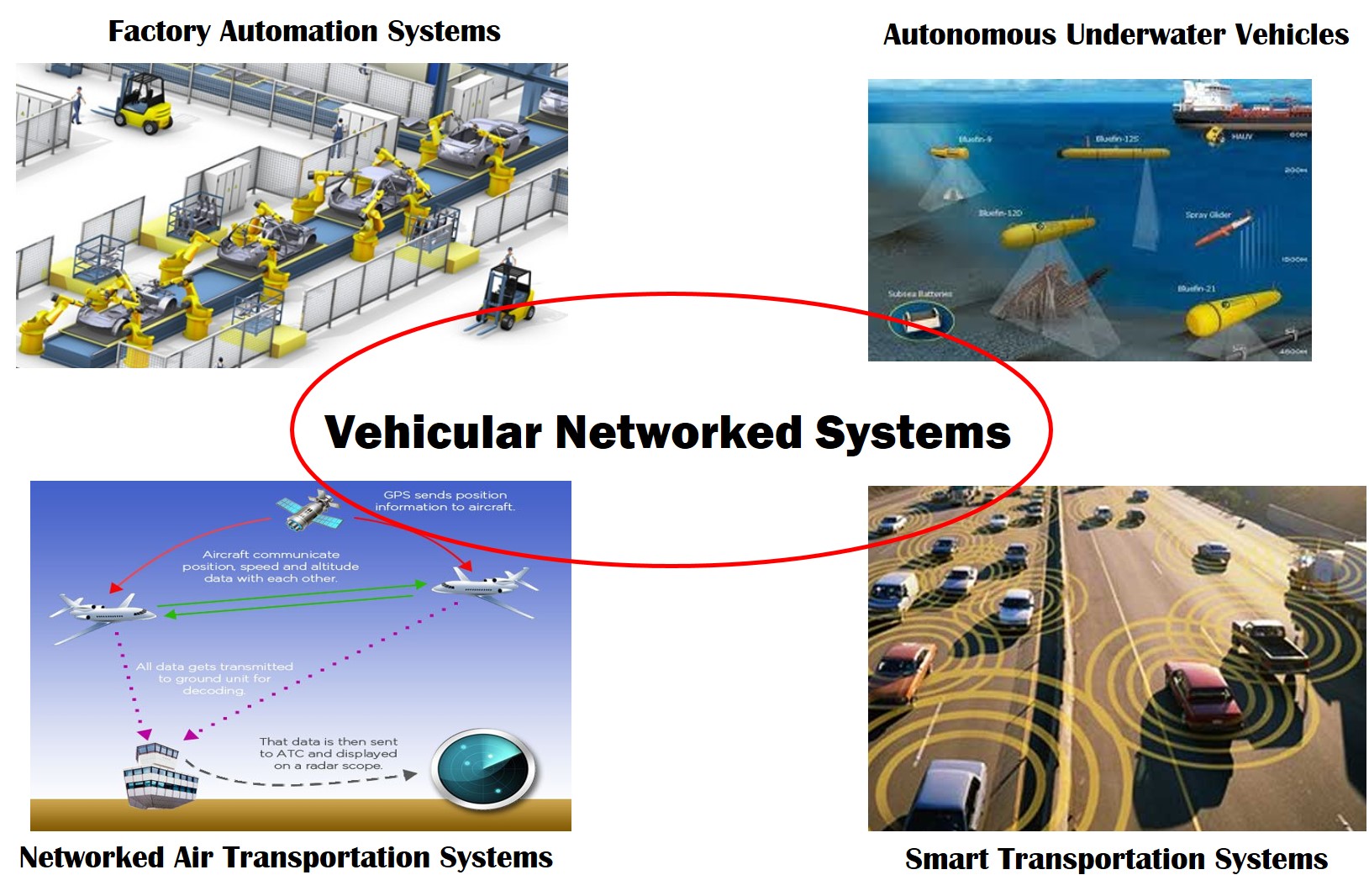

Vehicular Networked Systems (VNS) are Cyber-Physical Systems (CPS) where the communication, control and information processing technologies are integrated to achieve more safe and effective transport for autonomous vehicles. Examples include autonomous underwater vehicle systems, intelligent air transportation systems, smart transportation systems and smart factory automation systems. Resilient VNS has abilities to maintain situational awareness of their surrounding threats and take actions assuring a return to operational normalcy in a safe and efficient way. Research challenges:

|

Along this line of research, the main contributions of our work include

Related papers:

Resilient Control Under Denial-of-Service via Dynamic Event Triggering, The 2017 Asian Control Conference (ASCC 2017)

Tua A. Tamba, Yul Y. Nazaruddin and Bin Hu

Self-triggering in Vehicular Networked Systems with State-dependent Bursty Fading Channels, 2017

Bin Hu and Michael Lemmon

Co-design of Safe and Efficient Networked Control Systems in Factory Automation with State-dependent Fading Channels, 2016

Bin Hu, Yebin Wang, Philip Orlik, Toshi Koike-Akino and Jianlin Guo.

Event-Triggering in Three-Dimensional Leader-Follower Formation Control for Unmanned Aerial Vehicles, ASME DSCC 2016

Liang Sun and Bin Hu

Distributed Switching Control to Achieve Almost Sure Safety for Leader-follower Vehicular Networked Systems, IEEE Trans. Autom. Control (Full Paper), 2015

Bin Hu and Michael Lemmon.

Event Triggering in Vehicular Networked Systems With Limited Bandwidth and Deep Fading, IEEE CDC 2014 (Invited Paper)

Bin Hu and Michael Lemmon.

Using Channel State Feedback to Achieve Resilience to Deep Fades in Wireless Networked Control Systems, ACM HiCoNS, 2013

Bin Hu and Michael Lemmon.

Resilient Human Machine/Robot Systems: Modeling, Control, Optimization and Synthesis

|

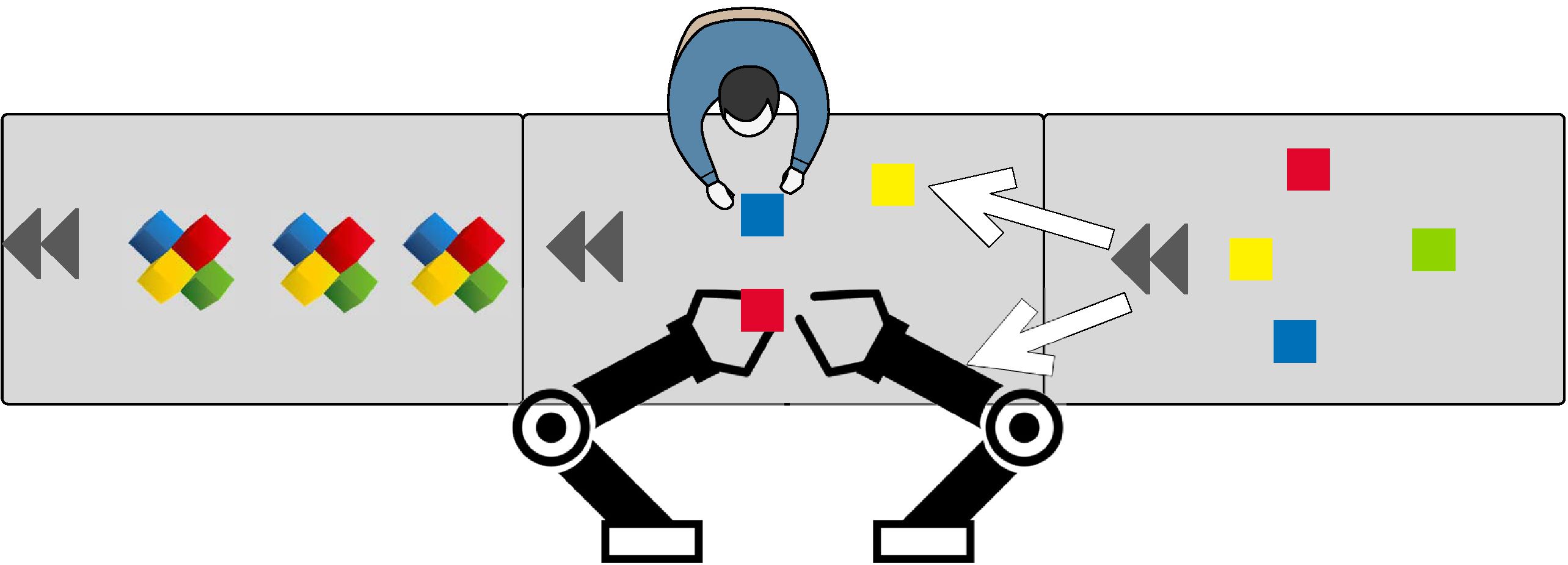

A human-machine system consists of human operators and automated machines that interact/collaborate with each other to accomplish complex tasks that are difficult for either humans or machines alone. Such human-machine systems, however, are subject to system failures caused by large and unexpected human uncertainties. The figure on the left shows a hybrid assembly example where assembly tasks are allocated to both human operators and automated robots. Prior work showed that human factors, such as human trust and fatigue, have paramount impact on human performance in task execution. Thus, unlike the resilience issues in unmanned autonomous systems, the resilience of a human-machine system relies on the resilience of machine and human as a whole, and therefore demands interdisciplinary approaches from both the engineering and psychology communities. |

Along this line of research, the main contributions of our work include

Development of stochastic hybrid human machine/robot framework that unifies the probabilistic evolution of human factors, such as human trust and fatigue, and dynamics of machine/robot for human machine/robot collaboration;

Design of computationally efficient algorithms to achieve optimal human machine/robot collaboration ;

Development of learning based optimal human-robot collaboration algorithms with temporal logic constraints.

Related papers:

Optimal Task Allocation for Human-Machine Collaborative Manufacturing Systems, IEEE RA-L/IROS, 2017

Bin Hu and Jing Chen.Toward Efficient Manufacturing Systems: A Trust Based Human Robot Collaboration, ACC, 2017

Bo Wu, Bin Hu and Hai Lin.A Learning Based Optimal Human Robot Collaboration with Temporal Logic Constraints, 2017

Bo Wu, Bin Hu and Hai Lin.Recognition of Car Warnings: An Analysis of Various Alert Types, CHI, 2017

Sabic Edin, Jing Chen, Mishler Scott and Bin Hu.

Big Data in Control, Optimization and Monitoring of Industrial Process Systems

|

Industrial processes are typically complex systems with high nonlinearity. The complexity lies in the fact that the process systems often consist of many subsystems having different dynamics that are physically connected. The system dynamics of these processes are difficult to be modeled using priori first-principle due to their high nonlinearity and various operational conditions. On the other hand, with the rapid development of computing, sensing and storing technologies, oceans of recorded process data become available and motivate data driven based approach as an attractive alternative for system monitoring, control and optimization. Research challenges:

|

Along this line of research, the main contributions of our work include

Development of a novel PLS framework that incorporates the advantages of neural network and Auto-regressive with eXogenous input (ARX) representations for nonlinearity and dynamic correlation among data.

Design of data-driven based multi-loop nonlinear internal model controller to achieve significant system improvement for practical chemical processes, such as chemical column and reactors.

Design of efficient data-drive based optimization method that ensures maximum economic profit for complex industrial processes by generating optimal transition behaviors among various operation conditions.

Related papers:

Multi-loop Nonlinear Internal Model Controller Design Under Nonlinear Dynamic PLS Framework Using ARX-neural Network Model, Journal of Process Control, 2012

Bin Hu, Zhao Zhao and Jun LiangMulti-loop Nonlinear Internal Model Controller Design Based On A Dynamic Fuzzy Partial Least Squares Model, Chemical Engineering Research and Design, 2013

Qinghua Chi, Zhao Zhao, Bin Hu, Yan Lv and Jung Liang.An Efficient Latent Variable Optimization Approach With Stochastic Constraints for Complex Industrial Process, Chinese Journal of Chemical Engineering, 2013

Zhengshun Fei, Kangling Liu, Bin Hu and Jun LiangMulti-loop Internal Model Controller Design Based On A Dynamic PLS Framework, Chinese Journal of Chemical Engineering, 2010

Bin Hu, Pingyou Zheng and Jun Liang